Chemical Engineering

-

Customer: COFCO Xishuangbanna strong fine Valley border trade in GuangxiClass Title: Chemical Engineering Product Title::TJG Fixed Material-lifting And Feeding MachineOverview: Since the seasonal planting materials , acquisition time is highly concentrated , if not dry easily rotten bad , bad storage . General drying equipment using high energy consumption, use of natural drying and affected by the weather , the company developed multi- belt drying equipment is ideal for drying the material.

-

Customer: Shanghai Jingwei 5 sets, Zhejiang Jin Di, Zhejiang cube, Yixing Hualong, exports from India, the Philippines,Class Title: Chemical Engineering Product Title::TJG Fixed Material-lifting And Feeding MachineOverview: Flour air dryer is mainly used in flour , sawdust drying wood industry is essential equipment. Because of these materials has the particularity flour : light weight, flammable, explosive .

-

Customer:Class Title: Chemical Engineering Product Title::PLG Series Continuous Disc Plate DryerOverview:

-

Customer:Class Title: Chemical Engineering Product Title::XZG Series Spin Flash DryerOverview: According to our many years of production experience, we can choose the XZG Series Spin Flash Dryer and Three-spiral Mixer to realize continuous production.

-

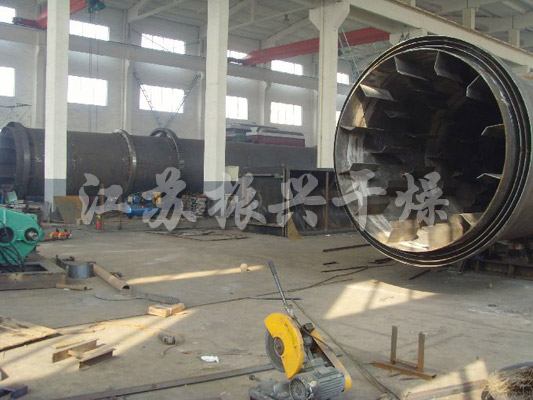

Customer:Class Title: Chemical Engineering Product Title::HZG Series Single Rotary Drum DryerOverview: Aluminum Hydroxide HZG Rotary Drum Dryer is a drying equipment with a high degree of mechanization, smaller resistance when the fluid pass through the cylinder, lower energy consumption, better adaptability to the materials.

-

Customer:Class Title: Chemical Engineering Product Title::DW Series Multi-Layer Mesh Belt DryerOverview: Activated carbon due to small particles, easy to float, high drying temperatures and other technical difficulties, has been no suitable dryer for drying. Aiming at the technology blank, the company's technology department alone developed the Activated Carbon Belt Dryer.

-

Customer:Class Title: Chemical Engineering Product Title::XZG Series Spin Flash DryerOverview: According to our many years of production experience, we can choose the XZG Series Spin Flash Dryer and Three-spiral Mixer to realize continuous production.

-

Customer:Class Title: Chemical Engineering Product Title::YPG Series Pressure Type Spray (Congeal) DryerOverview: ACR resin properties: moisture content of 37-40%, a viscosity of 2-7 cps, pH = 6-8, milky aqueous emulsion, 45% solids content of the liquid. According to the dried material requirements, we can choose the YPG-2000-type pressure spray drying equipment for continuous production.

-

Customer:Class Title: Chemical Engineering Product Title::XZG Series Spin Flash DryerOverview: Silicon carbide (SiC) is using quartz sand, petroleum coke (or coal), wood chips as raw material through high temperature resistance furnace smelting. In the modern C, N, B, and other non oxide high - tech refractory raw materials, silicon carbide is the most widely used and the most economical one.

-

Customer:Class Title: Chemical Engineering Product Title::XZG Series Spin Flash DryerOverview: On the basis of introducing and absorbing foreign advanced technology, our company successfully developed a new type of drying equipment-- Cryolite Flash Dryer.

-

Customer:Class Title: Chemical Engineering Product Title::XZG Series Spin Flash DryerOverview: Dye intermediates, also known as intermediate, refers to a variety of aromatic derivatives for the production of dyes and organic pigments. They are with aromatic hydrocarbons, benzene, toluene, naphthalene and anthracene from coal chemical and petrochemical as the basic raw material, and are made through a series of organic synthesis unit process.

-

Customer:Class Title: Chemical Engineering Product Title::LPG Series High Speed Centrifugal Spray DryerOverview: Under the action of the pump, the original solution with a 11-12% solids content is fed continuously into the "centrifugal spray tower" and evaporates quickly. Most of the products are discharged from the bottom of the tower through the discharge valve, and the remaining products enter into the cyclone separator and then to be separated out. Under the effect of high negative pressure, the high temperature exhaust gas enters into "dust removal tower", and the gas is discharged into the atmosphere by the high pressure air blower.

-

Customer:Class Title: Chemical Engineering Product Title::ZLG Series Vibration Fluidized Bed DryerOverview: Designed and manufactured by our company, the spray granulation fluidized bed dryer can be a very good solution to solve the 65% lysine drying. The dried products are dense spherical particles with uniform particle size. Not easy to absorb moisture, and the system has good continuous stability. The single machine production capacity can reach 20 000-50 000 tons/year.

1

All 13 , 1 - 13, Page 1/1