Chemical Engineering

Cryolite Drying Production Line

Application Client:Cryolite drying production line

Project Classification:Chemical engineering industry

Dryer Type:XZG Series Spin Flash Dryer

Project Description:On the basis of introducing and absorbing foreign advanced technology, our company successfully developed a new type of drying equipment-- Cryolite Flash Dryer.

On the basis of introducing and absorbing foreign advanced technology, our company successfully developed a new type of drying equipment-- Cryolite Flash Dryer. The Dryer has advanced technology, reasonable design, compact structure, wide application, high production capacity, good product quality, high efficiency, energy saving, one-time to complete the drying, crushing and sieving within one equipment, eliminate the pollution of the environment, the whole machine performance reached the international advanced technology level.

Cryolite Dryer Working Principle

The hot air enters into the bottom of the drier in tangent direction. Under the driving of the stirrer, a powerful rotating wind field is formed. The paste state materials enter into the drier through the screw feeder. Under the powerful function of the stirring vanes at high-speed rotation, the materials are distributed under the function of strike, friction and shearing force. The cake state materials will be smashed and contact the hot air fully and the materials are heated and dried. The dehydrated materials will go up with the hot-air flow. The step rings will stop and keep the big particles. Small particles will be discharged out of the drier from the center of the machine and the material will be collected by cyclone separator of dust collector. The wet or big particles will be swing towards to the wall by the centrifugal force function and the materials will be crushed again after fall down to the bottom.

Features of the Cryolite Dryer:

1. A variety of feeding device for selection, continuous and stable feeding, won't produce bridge phenomenon in the processing.

2. Set special cooling device at the bottom of the dryer, to avoid the material deterioration phenomenon in the high temperature zone at the bottom.

3. The special pressure seals and bearing cooling devices, effectively prolong the service life of the transmission part.

4. The special air distributing device, reduce the resistance of equipment, and improve the processing air volume of dryer effectively.

5. Drying chamber is equipped with graded rings and eddy pieces, material fineness and final moisture can be adjusted ( such as the final moisture of calcium carbonate can be adjusted to ≤0.1% ).

6. Compared with other drying methods, which can effectively increase the specific gravity of material.

7. Because high cycle speed and short staying time of material in drying chamber can effectively prevent the material sticking to the wall and heat-sensitive material deterioration, high efficiency, fast and large-scale production of small equipment can be got.

Applicable Materials

Inorganic: Borax, Calcium Carbonate, Hydroxide, Copper Sulfate, Iron Oxide, Barium Carbonate, Antimony Trioxide, Metal Hydroxides, Heavy Metal Salts, Synthetic Cryolite, and etc.

Organics:

Atrazine (Pesticides), Cadmium Laurate, Benzoic Acid, Germicide, Sodium Oxalate, Cellulose Acetate, Organic Pigments, and etc.

Ceramic:

kaolin, silica, clay, and etc.

Dyes:

Anthraquinone, Black Iiron Oxide, Indigo Pigments, Butyric Acid, Titanium Hydroxide, Zinc Sulfide, Azo Dye Intermediates, and etc.

Food:

Soy Protein, Gelatinized Starch, Lees, Wheat Sugar, Wheat Starch, and etc.

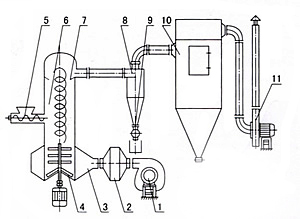

Schematic Structure

1. Blower 2. Heater 3. Air Distributor 4. Agitator 5. Screw Feeder 6. Dryer

7. Grader 8. Cyclone Separator 9. Star unloader 10. Dust Collector 11. Draft Fan

Project

Shaanxi Yanchang Petroleum (Group) Co., Ltd: Cryolite flash (including quick opening and cleaning door) + calcination、insulating layer + scraper conveyor + cooling screw conveyor,whole-process PLC control.

Flash dryer Performances:

|

Construction Unit |

Project Name |

Device Name |

Quantity |

Contract Price |

Acceptance Results |

|

Shandong Lukang Pharmaceutical Co., Ltd., |

Veterinary Drugs |

Flash Dryer |

2 |

1200 000RMB |

Production of 2 years |

|

Shandong fuyang Biotechnology Co., Ltd. |

Biological Protein |

Flash Dryer |

1 |

680 000 RMB |

Production of 1 years |

|

Shandong Sino-Agri United Biotechnology Co.,Ltd. |

Pesticides |

Flash Dryer |

1 |

550 000 RMB |

Production of 4 years |

|

Nanjing Red Sun Co., Ltd. |

Pesticides |

Flash Dryer |

2 |

700 000 RMB |

Production of 5 years |

|

Zhejiang Juhua Group Corporation |

dye |

Flash Dryer |

2 |

900 000 RMB |

Production of 3 years |

|

Shandong Haihua Group Co., Ltd. |

Pesticides |

Flash Dryer |

1 |

550 000 RMB |

Production of 3 years |

|

Henan Xindaxin Materials Co., Ltd. |

Silicon Carbide |

Flash Dryer |

2 |

900 000 RMB |

Production of 2 years |

|

Yangzhou Gelaide Technology Co., Ltd. |

Silicon Carbide |

Flash Dryer |

2 |

800 000 RMB |

Production of 1 year |

|

Changzhou Barone |

Zinc Carbonate |

Flash Calcination |

1 |

1400 000RMB |

Production of 1 year |

|

………….. |

|

|

|

|

|