Environmental protection engineering

Sludge Drying Production Line

Application Client:Shaoxing Yongfeng group, Shaoxing Jiade printing and dyeing, Shaoxing

Xinfa printing and dyeing……

Project Classification:Environmental protection engineering

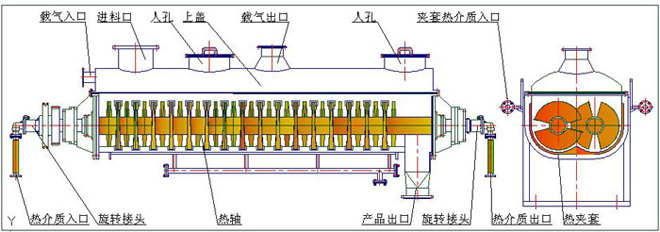

Dryer Type:JYG Series Hollow Paddle Dryer

Project Description:In the past, many chemical companies dumped the sludge outside the factory after dewatering by belt press filter. That will cause the pollution to surrounding environment. Now the country has banned the sludge outside pouring. Therefore, these enterprises need to fire after the sludge drying or use for the brickmaking in building materials factory. So the sludge drying will be a great potential project in the future.

Project introduction:

In the past, many chemical companies dumped the sludge outside the factory after dewatering of belt press filter. That will cause the pollution to surrounding environment. Now the country has banned the sludge outside pouring. Therefore, these enterprises need to fire after the sludge drying or use for the brickmaking in building materials factory. So the sludge drying will be a great potential project in the future. The hollow blade dryer developed by our company is especially suitable for printing and dyeing sludge, textile sludge, bleaching and dyeing sludge, biochemical sludge, petrochemical sludge, electroplating sludge, papermaking sludge and sewage sludge.

Working Principle:

The wedge type hollow blades are densely arranged on the hollow shaft, and the heat medium enters into the hollow blades through hollow shaft. The heat transfer area is very large within the effective unit volume, and the temperature of heat medium can be from 40℃ to 320℃, and it can be water vapor, or it can be hot water or heat conduction oil. Heat transfer medium enters into the shell heating jacket and the hollow stirring shaft through the rotary joint. The hollow stirring shaft has different internal structure according to the types of heat medium, so as to ensure the best heat transfer effect.

The steam is bubbled into the hollow blades and heating jacket to heat, at the same time, the heated dry air is bubbled into dryer for the further drying from the upper of discharge outlet. This greatly increases the drying intensity of the equipment. The evaporated water with the tail gas is discharged out of the dryer, after the filtration of bag filter, the dried powder will be recycled, and the wet air is discharged to the outside by the draft fan after the water removing dust.

Device Characteristics:

Low energy consumption: because of the indirect heating, there is not a large amount of air to take away heat, and set up the insulation layer in the outer wall of the dryer; for the pasty materials, the evaporation of 1KG water only needs 1.2KG water vapor.

Low system cost: the heat transfer area is very large within the effective unit volume, which shortens the processing time and reduces the size of equipment, so that greatly reduces the construction area and building space.

Wide range of materials: the selection of different medium can be used for the treatment of heat sensitive materials and the processing of high temperature materials. Commonly used mediums: water vapor, heat conduction oil, hot water, cooling water, etc.. It can be used in continuous production and intermittent operation, and it can be used in many fields.

Small environmental pollution: the carrying air quantity is very little, and the dust material entrainment is also very little. The closed circuit circulation can be used for the working condition of polluting materials or solvent to be recovered.

Low operating expenses: the normal operation of the device only needs one person per day. It has a low stirring speed and reasonable structure. The wear volume is small and maintenance costs are very low.

Stable Operation: due to the special compression and expansion effects of wedge blades, the material particle composition is fully contacted with the heat transfer surface. The material temperature, humidity and mixing temperature gradient are small in the axial section, so as to ensure the stability of the process

Typical Customers

Shaoxing Yongfeng group; Shaoxing Jiade printing and dyeing; Shaoxing Xinfa printing and dyeing

Shaoxing Wuming group; Shaoxing Huasheng printing and dyeing;

Shaoxing Jiangnan printing and dyeing

Shaoxing Xinyu group; Shaoxing Sanjie printing and dyeing; Shaoxing Hengda printing and dyeing;

Shaoxing Shumei printing and dyeing; Shaoxing bailiheng printing and dyeing;

Shaoxing Dongsheng printing and dyeing;

Jiangsu Yangnong Group; Guangdong Dongying printing and dyeing; Jiangsu Youshi chemical;

Jiangyin Tongda printing and dyeing; Shandong Zouping Changshan printing and dyeing;

Jiangsu Zhijiang chemical;

Shanxian Guanghui natural pigment; Foshan Gaoming Dongying textile; Chifeng Aobaohua mining;

Chongqing Shuangfeng chemical; Jiande Shuangchao calcium industry; COFCO (puree);

Renesola Ltd (silicon mud)...

Process Flowchart:

1.Carrier Gas Inlet 2.Feed Inlet 3.Manhole 4.Head Cover 5.Carrier Gas Outlet 6.Manhole

7. Jacket Heat Medium Inlet 8. Heating Jacket 9. Heat Medium Outlet 10. Rotating Joint

11. Products Outlet 12. Heating Shaft 13. Rotating Joint 14. Heat Medium Inlet