Environmental protection engineering

Sludge Dryer

Application Client:

Project Classification:Environmental protection engineering

Dryer Type:HZG Series Single Rotary Drum Dryer

Project Description:The mud material drying system developed by Jiangsu Zhenxing Drying is suitable for the drying of larger viscosity sludge, which can be used to dry the wet sludge of 85% or so, and the dry powder is the following 10%. Negative pressure operation of the sludge drying system, with the enhanced heat transfer device of direct heat transfer, material drying moisture control is convenient, the operation is flexible, allowing the flow of products has a larger range of fluctuations. In the system, the high temperature mechanical equipment is small, simple and reliable, simple structure, easy to clean, low failure rate, continuous operation, low maintenance cost, wide application.

Jiangsu Zhenxing Drying Equipment Co., Ltd. is one of the professional dryer manufacturers. After two years of hard work and research, our company's technical team has carried on lots of reform and innovation for the sludge dryer, and get high praise both within and outside the field of drying.

Overview of Sludge Dryer

The mud material drying system developed by Jiangsu Zhenxing Drying is suitable for the drying of larger viscosity sludge, which can be used to dry the wet sludge of 85% or so, and the dry powder is the following 10%. Negative pressure operation of the sludge drying system, with the enhanced heat transfer device of direct heat transfer, material drying moisture control is convenient, the operation is flexible, allowing the flow of products has a larger range of fluctuations. In the system, the high temperature mechanical equipment is small, simple and reliable, simple structure, easy to clean, low failure rate, continuous operation, low maintenance cost, wide application. The sludge drying machine system is widely used in activated sludge drying, sludge drying, sludge drying, sludge drying, printing and dyeing sludge drying, sludge drying, electroplating sludge drying, sludge drying, biological fermentation sludge and other sludge drying, and the drying of high moisture material such as various kinds of groove slag.

Working Principle:

The working principle of the new sludge drying machine system is as follows:

Through the chute, the sludge is sent into the dryer by feeder. With the rotation of the cylinder, the sludge is guided to the inclined lifting plate and elevated to the center of the cylinder, and then the dispersed falling materials will form a material screen. There will take place sludge preheating and moisture evaporation when the high temperature gas flow pass through the sludge screen. When the sludge fall and move to the active grate type wing plate, the materials will be mixed with the preheated grate type wing, and then the heat will be transferred to the material, so as to evaporate water. At the same time, the wing plates repeatedly lift up and float down materials, and the materials will contact and exchange heat with hot gas flow in the process of convection. The cleaning device buried in the materials slide down along the inside of arc-shaped lifting plate, which can sweep down the materials that adhered to the inner wall of the lifting plate. When the cleaning device turns to the vertical line with the cylinder together, it will have a drag operation on the back of arc-shaped lifting plate, which can sweep down the materials that adhered to the outer wall of the lifting plate. With the continuous rotation of the cylinder, the partial water is evaporated and the sludge gets further drying. At the same time, the cleaning device plays a breaking role to sludge ball, thus improving the drying rate. Finally the sludge becomes low moisture loose material after drying and be exhausted from discharge port. If you are interested in the sludge dryer project, you can contact our company to learn more detailed information. Choose the Zhenxing Drying, Guarantee the product quality.

Features:

1. The reasonable partition makes the material dispersion and throwing effect is better.

2.The unique arch-breaking and rapping devices can effectively solve the problems that the material is bonded with the body or lifting device, and the problems of the materials caking and movement is blocked during the process of drying.

3.The special lifting and dispersing device make the material-gas exchange efficiency is higher.

4. Adopt the concurrent flow drying technics of materials together with hot gas flow. The range of application is wide, and it kept the original activity of the material.

5. Automatic temperature monitoring and controlling system makes the system operation is more convenient and efficient.

6. Adopting the inverter technology to adjust the cylinder speed, so as to optimize the time of material contacting with the hot flue gas, and to improve the drying effect.

7. Optimized structure design, Extended equipment service life.

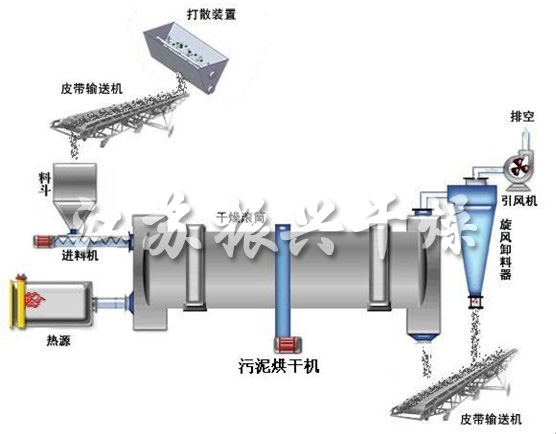

Production Flowchart of Sludge Drying

1. Saturated Steam or Heat Conduction Oil(150℃—160℃)

2. Wet Sludge Inlet(room temperature)

3. Exhaust Steam(85℃—95℃)

4. Hot Shaft

5. Head Cover

6. Hollow Blades

7. Condensate Water or Low Temperature Heat Conduction Oil(80℃—90℃)

8. Dried Sludge Outlet(72℃—80℃)

9. Heating Jacket

Rotary Drum Dryer