Environmental protection engineering

Electroplating Sludge Drying Equipment Engineering

Application Client:

Project Classification:Environmental protection engineering

Dryer Type:JYG Series Hollow Paddle Dryer

Project Description:Electroplating sludge is the "final state object" of the electroplating industry wastewater treatment, which contains a lot of copper, nickel, chromium, iron, zinc and other precious metals.

Electroplating sludge is the "final state object" of the electroplating industry wastewater treatment, which contains a lot of copper, nickel, chromium, iron, zinc and other precious metals.

Electroplating sludge mainly comes from the various electroplating effluent of industrial electroplating factory and the solid waste produced by the Liquid phase chemical treatment of electrolytic bath.Because of the different production processes and treatment processes,the chemical components of electroplating sludge is very complicated,which mainly contains chromium, iron, nickel, copper, zinc and other heavy metal compounds and soluble salts.

Electroplating sludge drying equipment developed by Zhenxing Drying is used to dry the electroplating sludge material, so that reduce the moisture content from more than 75% to 40%~65%. The dried material is evenly mixed with coal, and then the mixture is sent into a sintering furnace to sinter.

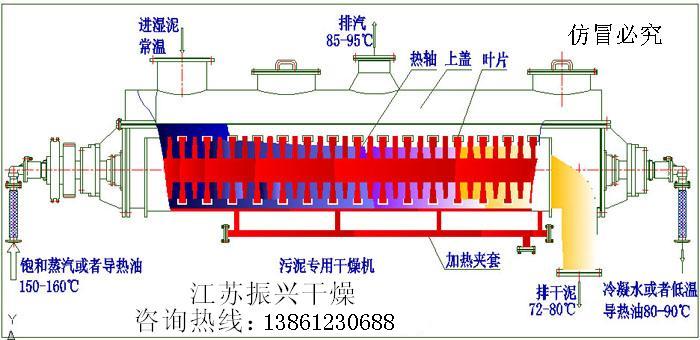

Schematic Structure:

1. Saturated Steam or Heat Conduction Oil(150℃—160℃)

2. Wet Sludge Inlet(room temperature)

3. Exhaust Steam(85℃—95℃)

4. Hot Shaft

5. Head Cover

6. Hollow Blades

7. Condensate Water or Low Temperature Heat Conduction Oil(80℃—90℃)

8. Dried Sludge Outlet(72℃—80℃)

9. Heating Jacket