Environmental protection engineering

Municipal Sludge Drying Equipment Engineering

Application Client:

Project Classification:Environmental protection engineering

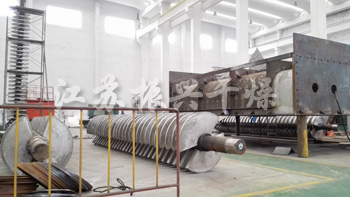

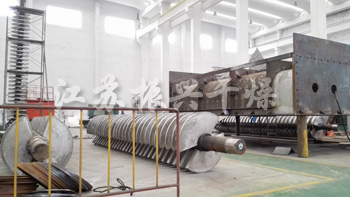

Dryer Type:JYG Series Hollow Paddle Dryer

Project Description:After the drying moisture processing in the sludge, and fitted with an appropriate proportion of coal ash, burned to produce heat energy to generate electricity. It is a solution to the final way of sludge, and it will have broad prospects in terms of sludge final disposal.

After the drying moisture processing in the sludge, and fitted with an appropriate proportion of coal ash, burned to produce heat energy to generate electricity. It is a solution to the final way of sludge, and it will have broad prospects in terms of sludge final disposal.

This process of Zhenxing sludge drying equipment includes feeding, drying, gas-solid separation, powder-dust collecting, moisture condensation, solid conveying and storage, etc.

There are many different types of sludge drying equipment, the common types are:

(1) Direct heating. The principle is convection heating. Typical equipment is rotary drum, fluidized bed and so on;

(2) Indirect heating. The principle is conduction heating or contact heating, there are spiral, disc plate, thin layer, disc, paddle and the like;

(3) Thermal radiation heating. There is belt, screw and so on.

Generally use indirect heating type: the heat of high temperature flue gas through a heat exchanger transfer to some kinds of medium. These mediums may be heat-conduction oil, steam or air. Medium is circulating in a closed loop, and is not in contact with the drying material. The heat is normally discharged with flue gas after partially utilizing.

Municipal sludge: the initial moisture is 62%; the final moisture is 5%.

Processing capacity: 100t / day.

Heat source: heat-conduction oil.

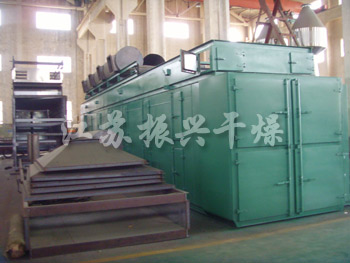

According to the above drying requirements, combined with our company many years of production experiences, we selected a set of KJG-240 type hollow wedge blade dryer (four axis) and a set of DW2 x 20 type multi-layer mesh belt dryer for continuous production.The material is made of stainless steel 304 at the place ofmaterial passing, the other is carbon steel.