Food Engineering

Dehydrated Vegetable Production Line

Application Client: Russia (potato), Pakistan (onion), Vietnam, Thailand, Philippines, Indonesia

Project Classification: Food Industry

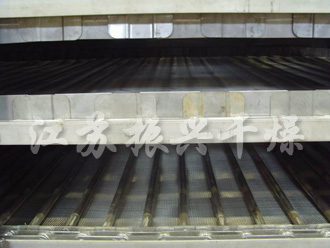

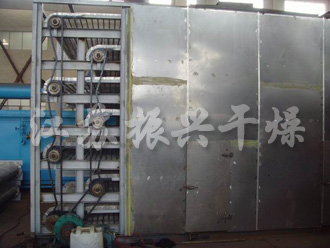

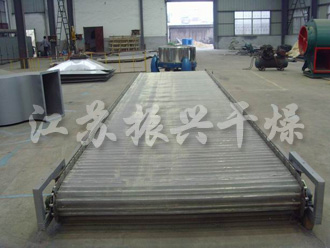

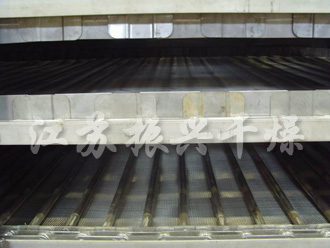

Dryer Type: DWT Series Dehydrated Vegetable Belt Dryer

Description:

Introduction:

- DWT series vegetable dehydration dryer is developed base on traditional mesh belt dryer. The dryer is widely applicable to all types of local and seasonal vegetables, herbs, fruits, such as cassava, garlic, pumpkin, konjac, radish, yam, bamboo shoots, and etc.

- Zhenxing Drying is the most experienced manufacturer for vegetable drying equipment. Our technical staffs have gone to the customer’s factory for equipment commissioning and we have paid follow-up service in order to collect practical technical information for further equipment improvement. We have combined the advanced technology from the other countries and the vegetable dehydration dryer have been developed to the third generation so far.

Working Principle:

1. The material is distributed to the mesh belt evenly by the feeder. The size of stainless steel mesh is 12-60mm mesh. The transmission device will moves the mesh belt around the dryer. The dryer consist a several drying units and each unit has individual hot air circulation system. Part of the exhausted gas is exhausted by an exhaust fan. The waste gas is controlled by an adjusting valve. The hot air will move up and down when the material moving from the top layer to the bottom layer. This process will evaporate the water from the material when the mesh belt moves slowly. The running speed of the conveyer belt can be adjusted according to the material property. The dried material will be automatically discharged to a collector. The circulation units can be equipped according to the user’s requirement and the production demands.

2. For dehydrated vegetables, the general three sets of equipment are used in series, which is divided into the first dry section, the middle section and the final dry section. In the first dry section, because of the high water content and poor air permeability, it is used to store the material thickness, the fast running speed and the higher drying temperature. In the first dry section, the dry gas temperature can be as high as 120℃. At the end of the dry period, the material residence time is 3-6 times of the initial dry section, and the thickness of the material is 2-4 times of the initial stage. For the material temperature no more than 60℃, can be used around 80℃ of dry gas. The performance of belt dryer can be better by using multi segment combination, and the drying is more uniform.

FEATURES:

(1) No pollution, high thermal efficiency (60%-75%)

(2) Rapid heating

(3) Easy for installation

(4) Low cost and long service life

(5) No accumulation of dust

(6) Energy saving

TYPICAL PROJECTS:

- COFCO Group

- Dozens of domestic agricultural products processing factory (Golden pear, kudzu root, almond, edible bacteria, day lily, bamboo leaves, watermelon seeds, plum, walnut, shallot, garlic…).

- Export Russia (potato), Pakistan (onion), Vietnam, Thailand, Philippines, Indonesia, etc.