Food Engineering

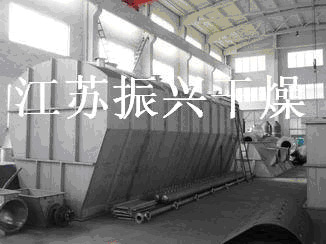

Koji Special XF Boiling Dryer

Application Client: A famous company in HUBEI.

Project Classification: Food Industry

Dryer Type: XF Series Horizontal Boiling Dryer

Description:

Working Principle:

The granular solid material is fed to fluidized bed dryer by the feeder. The blower will blows the filtered clean hot air heated into the fluidized bed at the bottom of the distribution plate and fluidization to gas-solid heat and mass exchange to heat the solid material. The dried material is discharged from the discharge outlet. The exhaust gas is discharged from the top of the fluidized bed and the solid power will be collected by the cyclone separator or cloth bag duster.

Features:

This fluid-bed is round structure. So it avoid died corner.

Inside the hopper there is a stirring device in order to avoid agglomeration of raw material and forming canal of flow.

The dump method is used to unload material, so it is convenient and quick, and can be designed according to the requirement.

Under the negative pressure condition, the air flow is filtered, so the operation is simple and easy to clean.

Fast drying speed, uniform temperature, each batch of drying time is generally 20-30 minutes.

Main Technique Characteristic:

The host of air dehumidification refrigerator used the international advanced technology. The compressor adopts high performance induction motor, starting smoothly. Its performance is superior, running safety, stability and maintenance cost is low.

Material temperature and steam flow are controlled by proportional valve. It can accurately adjust the steam flow, to ensure that the active ingredients of the material. We use the constant pressure air distributor and leak proof material punching plate, so the air distribution uniformity, no dead. The fluidization effect is good, no occurrence of channeling, slugging phenomenon, uniform drying.

We have a special way of feeding and discharging. It has the effect of sealing, dispersing and breaking the material, which is fast, convenient and thorough. In all corners of XF boiling dryer, the circular smooth transition is used, and the polishing process is used.

It is equipped with cleaning, disinfection device. Cleaning and disinfection is convenient. It meets the requirements of GMP standards.

The powder in the tail gas can be recovered and treated. When the tail gas is fully up to standard, it can be discharged.

Under the condition of low temperature drying, the temperature of the air can be controlled by the dry material at different temperature and time. To improve the drying efficiency of the equipment, shorten the drying time.

The main engine uses effective insulation measures, the system works in the micro negative pressure environment, without any dust leakage. The bag dust collector is used to monitor the pressure difference, and the stability of the system is not affected by the tail gas leakage.

Electric control system is composed of the field sensor, electric cabinet, instrument, PLC, touch screen, control components, wires, cables, etc. The dryer uses the PLC program control loop, the touch screen animation display technological process. It has operability. The automatic tracking of the fuzzy technology is realized by using variable parameters (including air flow, air pressure, inlet temperature, etc.). This can be adapted to the different material of a machine with more dry requirements.