Environmental protection engineering

Printing & Dyeing Sludge Dryer Project

Application Client:

Project Classification:Environmental protection engineering

Dryer Type:JYG Series Hollow Paddle Dryer

Project Description: Jiangsu Zhenxing Drying has designed and developed a paddle dryer. The wedge type hollow blades are densely arranged on the hollow shaft, and the heat medium enters into the hollow blades through hollow shaft.

Working Principle:

Jiangsu Zhenxing Drying has designed and developed a paddle dryer. The wedge type hollow blades are densely arranged on the hollow shaft, and the heat medium enters into the hollow blades through hollow shaft. The heat transfer area is very large within the effective unit volume, and the temperature of heat medium can be from 40℃ to 320℃, the heat can be hot water vapor, and it can also be a liquid type medium, such as hot water or ,heat conduction oil and so on. The heating mode of the device is an indirect conduction heating, and the heat is not carried away by the air, so almost all of the heat is used to heat the material. Heat loss is only the heat dissipation through the body insulation layer to the environment. Heat transfer surface of the wedge-shaped blade has the self-cleaning function. The relative movement between material particles and wedge-shaped surfaces can produce a washing effect. Therefore it can wash away the materials that attached to the wedge type surface, so as to make the heat transfer surface kept clean during the running of the machine. The shell body of the paddle dryer is a Ω-type, and the paddle dryer is generally installed with two or four hollow stirring shafts within the shell body. The sealing end cover and the upper cover are installed on the shell body, which can play its full role in preventing the leakage of the material dust.

Heat transfer medium enters into the shell heating jacket and the hollow stirring shaft through the rotary joint. The hollow stirring shaft has different internal structure according to the types of heat medium, so as to ensure the best heat transfer effect.

Features:

Low energy consumption: because of the indirect heating, there is not a large amount of air to take away heat, and set up the insulation layer in the outer wall of the dryer; for the pasty materials, the evaporation of 1KG water only needs 1.2KG water vapor.

Low system cost: the heat transfer area is very large within the effective unit volume, which shortens the processing time and reduces the size of equipment, so that greatly reduces the construction area and building space.

Wide range of materials: the selection of different medium can be used for the treatment of heat sensitive materials and the processing of high temperature materials. Commonly used mediums: water vapor, heat conduction oil, hot water, cooling water, etc.. It can be used in continuous production and intermittent operation, and it can be used in many fields.

Small environmental pollution: the carrying air quantity is very little, and the dust material entrainment is also very little. The closed circuit circulation can be used for the working condition of polluting materials or solvent to be recovered.

Low operation cost: the normal operation of the device only needs one person per day. It has a low stirring speed and reasonable structure. The wear volume is small and maintenance costs are very low.

Stable operation: due to the special compression and expansion effects of wedge blades, the material particle composition is fully contacted with the heat transfer surface. The material temperature, humidity and mixing temperature gradient are small in the axial section, so as to ensure the stability of the process.

Application:

The paddle dryer developed by Zhenxing Drying has been successfully used in environmental protection, food, chemical, petrochemical, industrial sludge and other fields.

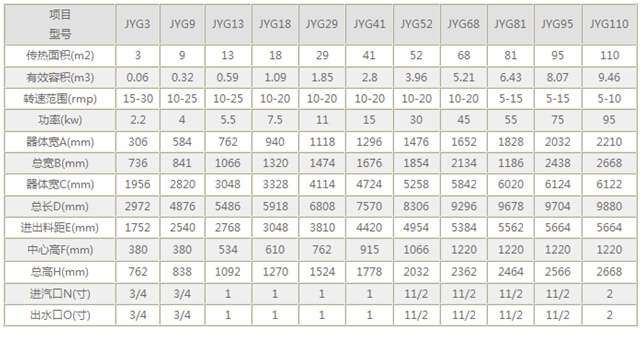

Technical Parameters: