Medical engineering

Traditional Chinese Medicine Extracts Drying Engineering

Application Clients: GUIZHOU BAILING GROUP PHARMACEUTICAL CO.,LTD.

Beijing Tong Ren Tang Group Co., Ltd.

JING BRAND Co., Ltd.

Project Classification: Other engineering industries

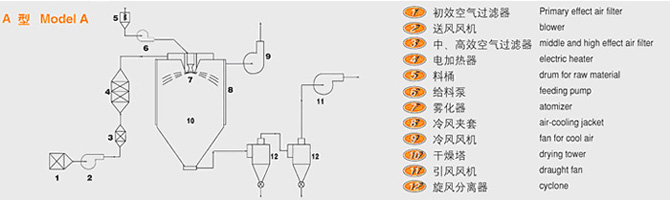

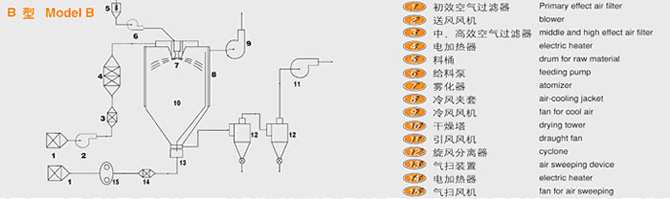

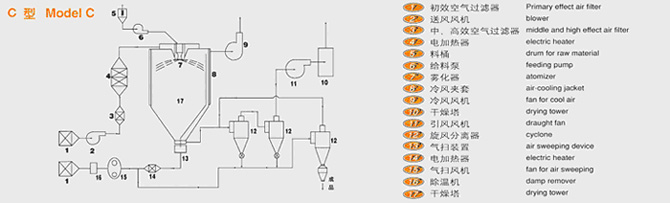

Dryer Type: ZLPG Series Chinese Herbal Medicine Extract Spray Dryer

Description:

Engineering Introduction:

In recent years, traditional Chinese medicine extract drying technology made significant progress, advanced extract drying technology and equipment has been the promotion, but for study on the drying process optimization and equipment improvements is still an urgent need to strengthen.

According to the present situation of its development, we analyze the advantages and disadvantages of different drying methods, and sum up the appropriate drying method to improve the quality of it.

This project will focus on the Chinese medicine spray drying engineering. It is the application of centrifugal spray drying technology in specific material drying. It can make the material dispersed into fine particles, and to make full contact with the hot air, complete the instantaneous drying, forming powder products. It solves some problems of LPG high speed spray dryer in traditional Chinese medicine extract

drying.

Working Principle:

After fresh air is filtered and heated, it enters into the air distributor which on the top of the drier. The hot air in spiral form equably enters into the drying room. When liquid raw material is passed through the high-speed centrifugal sprayer on the top of the tower, it will be rotated and sprayed into the extreme slim mist liquid beads. Raw material can be dried to the final products instantly while it contact with the heated air. Finished products are discharged continuously from bottom of the drying tower and cyclones segregator. Wasted air is discharged from the blower.

Advantages:

1. In order to prevent the phenomenon of sticky wall, the equipment is equipped with the cooling structure of the air cleaning wall and the tower wall, which effectively prevents the Sticky wall coking of the product. Improve product quality and yield.

2. Special cold air supply system. The dry products and wet air are separation timely, to avoid the product of moisture adsorption agglomeration.

3. It uses three levels of air purification, so that the wind can reach 30 level requirements;

4. It adopts the quick opening device, which is suitable for the production of many varieties;

5. Materials were collected using two stage cyclone dust removal device or a first class cyclone dust collector and wet dust collector;

6. Spray tower size and configuration according to the nature of the material to make a suitable adjustment, make it more practical;

7. It can choose PLC control, program control system in the screen display;

8. The design and production of the whole drying system conforms to the requirements of GMP standard;

Engineering Case:

GUIZHOU BAILING GROUP PHARMACEUTICAL CO.,LTD.

Beijing Tong Ren Tang Group Co., Ltd.

JING BRAND Co., Ltd.

Shanghai Hui CI Group