Food Engineering

Project Overview:

In recent years, traditional Chinese medicine extract significant progress in drying technology , advanced technology and equipment to extract dried to a certain promotion, but research equipment for the drying process optimization and improvement is still an urgent need to strengthen . Revitalization drying realistically according to the status of the development of Chinese medicine extract drying technology for vans drying, spray drying , vacuum drying principle of common drying technology , equipment status and technical characteristics , analyzes the different drying methods used for medicine extract drying the merits and concluded that a reasonable choice of appropriate drying methods for different characteristics in order to improve the quality of Chinese medicine extract of the finished product . This project focuses on medicine extract spray drying engineering, medicine extract high-speed centrifugal spray device is a centrifugal spray drying technology in the dry materials in particular , but also allows the use of high-speed centrifugal atomization into fine material dispersion , and the hot air full access to complete instant dried to form a dry powder device finished . The drying equipment is designed to solve medicine extract and plant extract spray dryer , which effectively solve the original LPG high-speed Chinese medicine extract spray dryer drying appear in many problems .

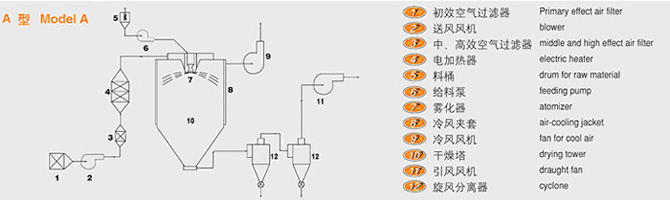

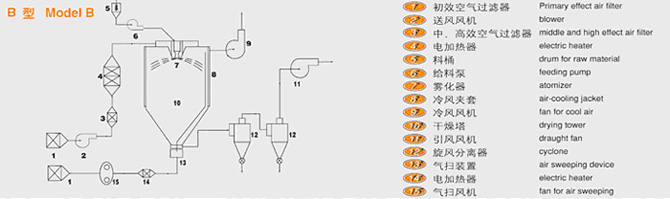

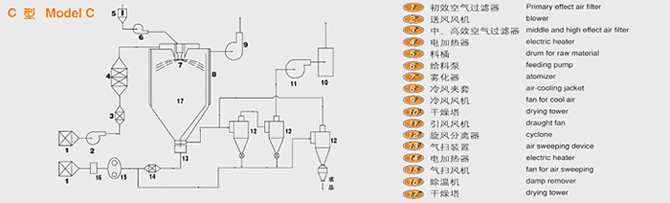

How it works:

Medicine extract high-speed centrifugal spray device is a centrifugal spray drying technology in the dry materials in particular , but also allows the use of high-speed centrifugal atomization material dispersed into a mist , full contact with the hot air of the complete instant dry , powdered form finished drying apparatus .

Advantage reflects :

1 , in order to prevent physical division produces sticky wall equipment with air- swept wall jacket cooling tower wall structure, effective way to eliminate the sticky wall coking products . Improve product quality, yield.

2 , the unique cold finished concentrate feed system , the dried finished promptly heat the wet air separation system to avoid agglomeration of the finished product may be produced absorbent resurgence .

3, into the air dryer uses three air purification, the inlet air reaches 300,000 requirement ;

4, using quick punch selected device, suitable for multi-species production requirements ;

5 , the material collected using two cyclone dust collector or a cyclone dust + wet scrubber ;

6 , the size and configuration of the spray tower FITNESS adjusted according to the physical nature of families , to make it more practical ;

7 , optional PLC control , program control system screen display ;

8 , the entire drying system design meets the requirements of GMP ;

Case : Guizhou Bai Ling , Beijing Tong Ren Tang, Jin licensing Co. , the Department of Ci Group, Anhui Bozhou Pieces , Zhejiang forget agriculture, pharmaceutical Ningbo , Zhejiang Hisun , Hyde pharmaceutical, Chongqing Tai Ping Pharmaceutical