Industry News

Working Principle Of Fluidized Bed Sludge Drying Equipment

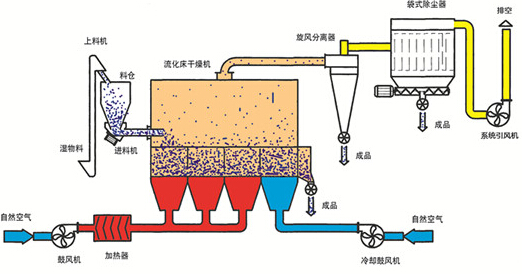

The fluidized bed sludge drying equipment is different from other drying equipment. Its dewatering sludge will be sent to the sludge measurement and storage bin. The sludge is sent to the sludge drying equipment by the special pump, and the sludge is allocated by the feed port. The equipment is composed of three parts, bellows, fluidized bed and suction hood.

The bellows under fluidized bed sludge drying equipment. It can make the circulating gas partial stream sent to all of the different regions by installing in the bottom of a gas distribution plate to the inert fluidizing gas to distribute out. As the heat source of the heating oil will flow through the middle section of the drying equipment to dry areas. Increase the temperature of the fluidized bed. The sludge is directly dried in the fluidized bed.

Suction cover in the top of the device, the main function is to separate the dry particles in the circulating gas, so that the circulating gas to carry out the drying out of the water vapor and dust together to leave the drying equipment. The separated sludge particles are sent to the cooler. The cooling sludge particles will be sent to the discharge port, packing bag.